Material Handling

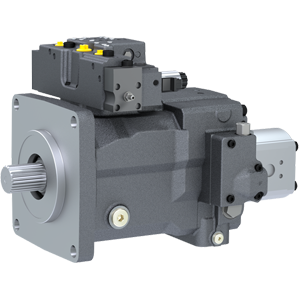

1x HPV 210-02 TC Displacement size from 55 to 280 cc variable pumps for closed circuit operation

Learn More

1x HPV 210-02 TC Displacement size from 55 to 280 cc variable pumps for closed circuit operation

Learn More

2x HMF 135 - 02With integrated swing drive functions fixed displacement motors with integrated swing drive functions

Learn More

2x HMF 135 - 02With integrated swing drive functions fixed displacement motors with integrated swing drive functions

Learn More

2x HPR 280 - 02 E1L Pump Tandemfor open and closed loop operation

Learn More

2x HPR 280 - 02 E1L Pump Tandemfor open and closed loop operation

Learn More

2x VT4 Directional Control Valves LSC VT MODULAR

Learn More

2x VT4 Directional Control Valves LSC VT MODULAR

Learn More

1x LINC 1, CEB 16/50 Linde Electronic control units of the LINC series feature high mechanic and electric robustness

Learn More

1x LINC 1, CEB 16/50 Linde Electronic control units of the LINC series feature high mechanic and electric robustness

Learn More

Linde Standard Product Portfolio

20 t - 120 t

Application Example

120 t

Equipment

1x HPV 210-02 TC (pump for swing drive)

2x HMF 135-02 (motors for swing drive)

2x HPR 280-02 E1L (pump tandem)

2x VT4 (directional control valves)

1x LINC 1, CEB 16/50 (electronic control unit)

Advantages

- rotation independently of the remaining hydraulics system

- precise rotating mechanism positioning via pre-controlled pump displacement feedback system

- defined, load-independent and thus reproducible run-out behaviour

- dosable countering

- the function “Turn in closed circuit” is increasingly beneficial for smaller material handling machines

Options

- customer-specific adjustment of the rotating mechanism dynamics – even on site

- energy recovery from the rotating mechanism

- stationary material handling machines

- electric motor as primary drive

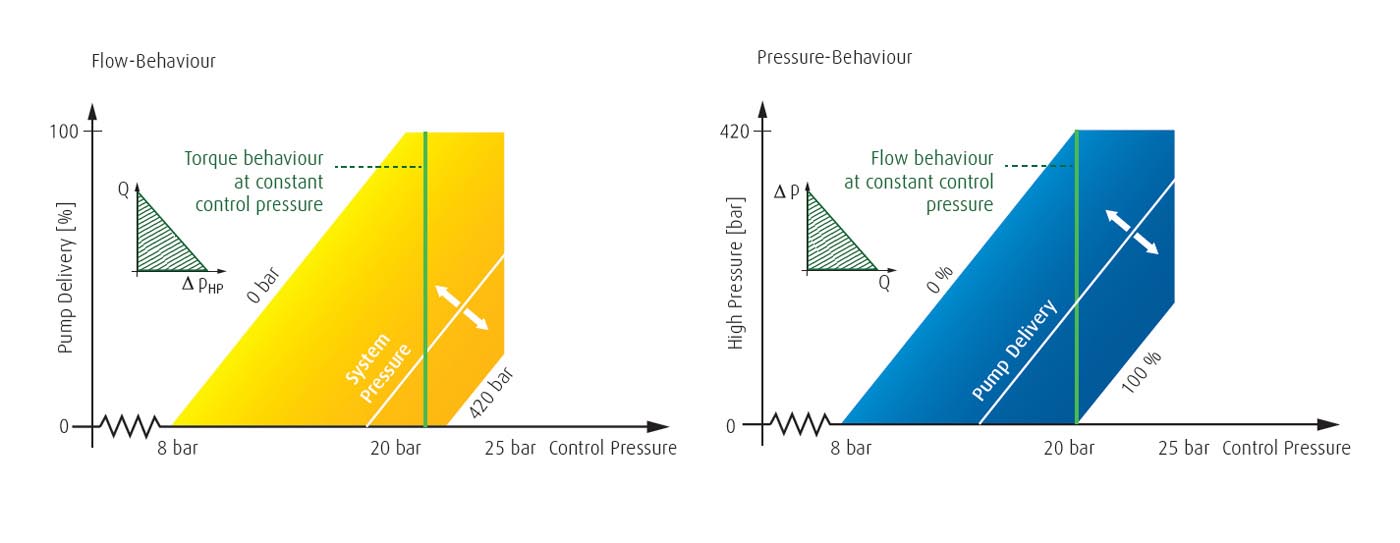

Machines that rotate a lot in their day-to-day work, such as the material handling machine shown here, benefit from a slewing gear in a closed hydraulic circuit. This means the rest of the machine can be optimised to the work functions, regardless of the rotating mechanism performance. The configuration shown uses two fixed displacement motors in combination with a variable displacement pump with torque control. This combines a hydraulic proportional flow characteristic with a torque control characteristic. During acceleration, the pump swivels quickly thanks to the volume control and increases the torque in direct proportion to the acceleration setting of the joystick. The torque characteristics of the control dominate the movement. The movement is dynamic but never jerky, even when re-accelerating out of a run-out phase.

The pump control forms the basis for load-independent, customisable run-out of the upper carriage in the neutral position of the joystick. Its position feedback control compensates for load influences. The mechanically pre-set run-out behaviour of the upper-carriage when the joystick is in the neutral position is the same for every boom distance and clamshell load. During countercontrol, the run-out angle can be reduced additionally in a dosed manner. This transfers the core features of the LinDrive driving experience to the working hydraulics system: precision, dynamics and reliability with unrestricted machine control.

The system is supplemented by the open circuit as a dual circuit setup. As such, significant lifting power can be achieved regardless of the swing movement. A self-regulating pump tandem and two valve blocks efficiently serve the different energy levels of the remaining actuators. The result is a dynamic machine that is easy and sensitive to operate for very high material handling performance with minimal loss, which does not cause fatigue.

Proslav district, 3 Zhasmin Str.

4015 Plovdiv, Bulgaria

Tel.: +359 32 240033

Service manager: +359 885 899 692

Assistant: +359 885 899 691

Email: office@baggerhydraulik.com

Website: baggerhydraulik.com