Hydraulic Auxiliary Drives

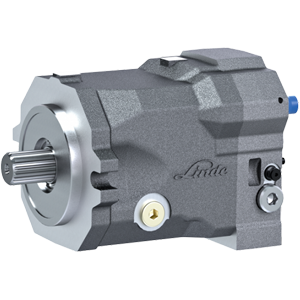

1x HPV 75-02 E1 Displacement size from 55 to 280 ccVariable pumps for closed circuit operation

Learn More

1x HPV 75-02 E1 Displacement size from 55 to 280 ccVariable pumps for closed circuit operation

Learn More

1x HMF 105-02 Displacement size from 28 to 135 cc Fixed displacement motors for open and closed circuits

Learn More

1x HMF 105-02 Displacement size from 28 to 135 cc Fixed displacement motors for open and closed circuits

Learn More

Linde Standard Product Portfolio

100 kW – 200 kW

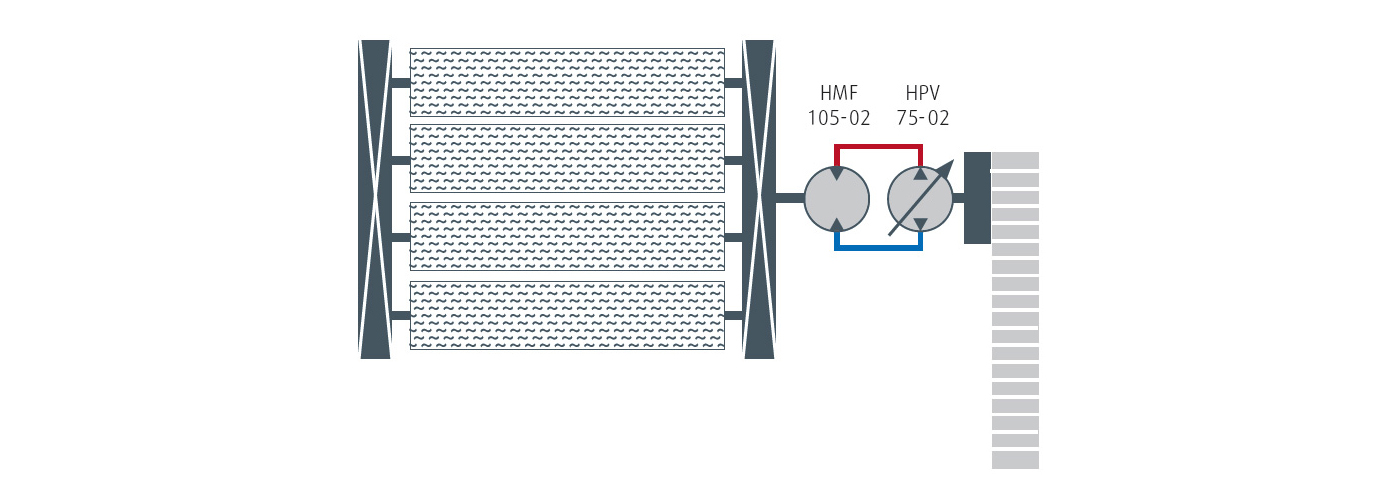

Application Example

160 kW (Harvester Feed System)

Equipment

1x HPV 75-02 E1

1x HMF 105-02

Advantages

- boost circuit is generally available from the propel drive

- safety

- functionality

- precision and dynamics

- degree of freedom in design and configuration

- electronic control/regulation is possible

Outstanding harvesting performance can only be achieved through interaction of all parts of the machine. Propel and auxiliary drives must be matched to each other. Hydrostatic drive systems from Linde offer many advantages for the overall system. Their compact design allows Linde hydraulic motors to be mounted exactly where the torque is required. They can therefore replace rigid shafts for power transmission. For the designer, this gives a significantly greater degree of freedom to achieve a striking design and satisfy the enhanced power requirements of modern machines.

The use of hydraulics offers additional functional and safetyrelated advantages: The stepless speed adjustment of a hydraulic harvesting crop intake allows stepless adjustment of the cutting length for the chopped forage – always ensuring the best possible outcome for both stock and harvesting target. Hydraulics is the best way to achieve a quick stop if stones or metal objects aredetected, without overstressing the mechanical components involved.

The central control of the units allows the same signal to be used for stopping both the chopping unit and the propel drive. It is also advantageous to use a hydraulic drive for the fan system in the machine. The fan speed can be intelligently and steplessly adjusted independently of the diesel engine speed.

The trend is moving towards hydraulic drives for fans, intake, choppers, transport belts, thresher drive, scraper floor, and much more. Linde Hydraulics is leading the way.

Proslav district, 3 Zhasmin Str.

4015 Plovdiv, Bulgaria

Tel.: +359 32 240033

Service manager: +359 885 899 692

Assistant: +359 885 899 691

Email: office@baggerhydraulik.com

Website: baggerhydraulik.com