Concrete Pump

A

A

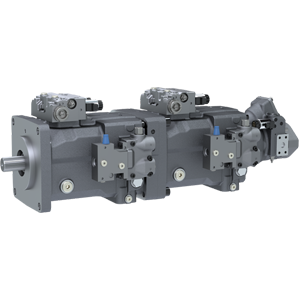

1x MPR 50 Medium pressure for heavy duty operationfor open circuit operation

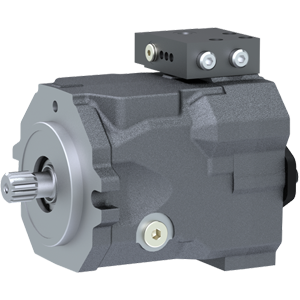

Learn More2x HPV 210-02 E1P fast swiveling Displacement size from 55 to 280 ccvariable pumps for closed circuit operation

Learn MoreB

1x MPR 50 Medium pressure for heavy duty operationfor open circuit operation

Learn More2x HPV 210-02 E1P fast swiveling Displacement size from 55 to 280 ccvariable pumps for closed circuit operation

Learn MoreB

1x HPR 55-02 LPDisplacement size from 55 to 165Dself-regulating pump for open loop operation

Learn MoreC

1x HPR 55-02 LPDisplacement size from 55 to 165Dself-regulating pump for open loop operation

Learn MoreC

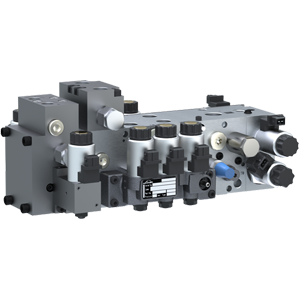

1x VW12M3 working hydraulics valves LSC VT Modular

Learn MoreD

1x VW12M3 working hydraulics valves LSC VT Modular

Learn MoreD

1x LINC 2Linde Electronic control units of the LINC series feature high mechanic and electric robustness

Learn More

1x LINC 2Linde Electronic control units of the LINC series feature high mechanic and electric robustness

Learn More

Linde Standard Product Portfolio

15 m - 70 m

Application Example

55 m

Equipment

2x HPV 210-02 E1P fast swiveling (conveying pumps)

1x MPR 50 (switching pump)

1x HPR 55-02 LP (working hydraulics pump)

1x VW12M3 (working hydraulics valves)

1x LINC 2 (electronic control unit)

Advantages

- exact synchronization of the pumps

- good filling degree of the cylinder

- high conveying speed

- low mast vibrations

- robust hydraulic units

- low noise emission

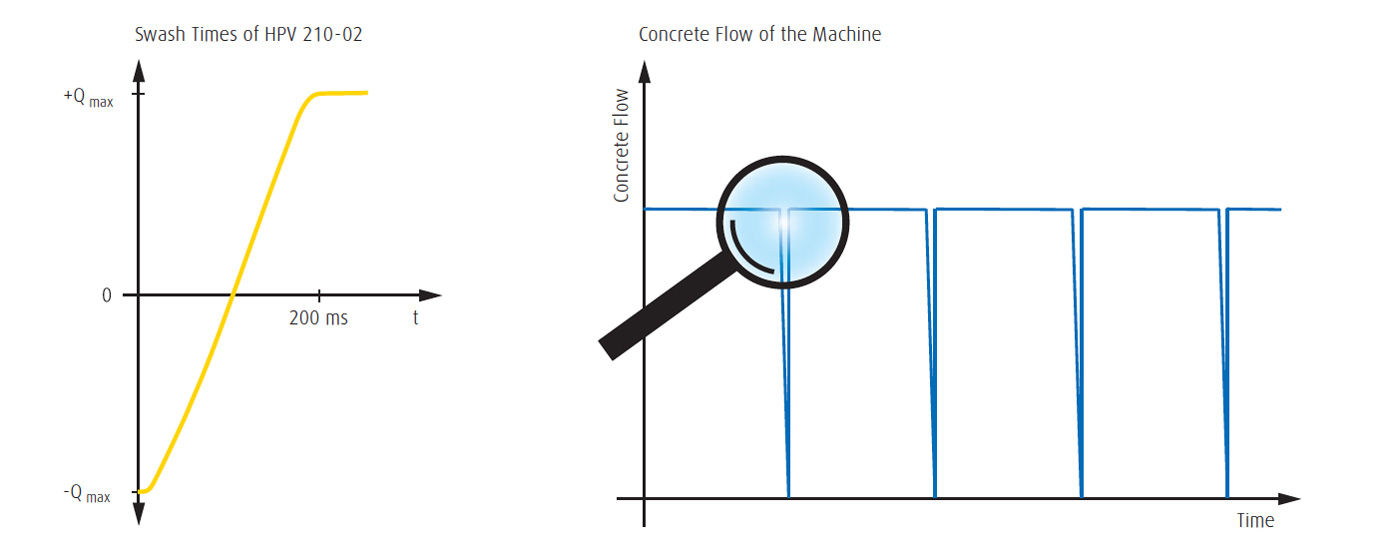

High and steady concrete flow characterizes a premium concrete pump. It benefits from the smooth running behaviour of the Linde components, which help to reduce mast vibrations and noise emissions to a minimum. The assembly realizes up to 36 conveying cycles per minute which results in an almost constant concrete flow. The two conveying cylinders are driven by two HPV variable displacement pumps, which operate in a push-pull mode. Each pump features 210 cc/rev displacement and is optimized to this application. This is done by an optimized signal flow and an increased control pressure of 40 bar which enables the pumps to swivel between the two displacement maxima in only 210 ms. This makes them one of the fastest pumps on the market in this scale.

By operating in a closed hydraulic circuit, the system only needs a small amount of circulating oil. Like every controller available for the HPV, the E1P type represented here is working independent of the load. Since the control signal for the pump is always the same, there is no need to change the software in order to adapt the machine to different conveyor heights or different concrete textures. This is also true for the MPR 50 medium pressure pump which powers the switching cylinder of the transfer tube. The MPR 50 is in this case set at minimum displacement which guarantees a minimum flow and thus continuous movement of the switch even at fault. This prevents concrete from hardening at this neuralgic spot of the machine and saves maintenance work. The high control precision eases the synchronization of the pumps and is beneficial for smooth running behaviour and low wear.

The other components of the open hydraulic circuit are fed by a HPR 55-02 self-regulating pump which is also very silent due to its pulsation damping SPU unit.

Proslav district, 3 Zhasmin Str.

4015 Plovdiv, Bulgaria

Tel.: +359 32 240033

Service manager: +359 885 899 692

Assistant: +359 885 899 691

Email: office@baggerhydraulik.com

Website: baggerhydraulik.com